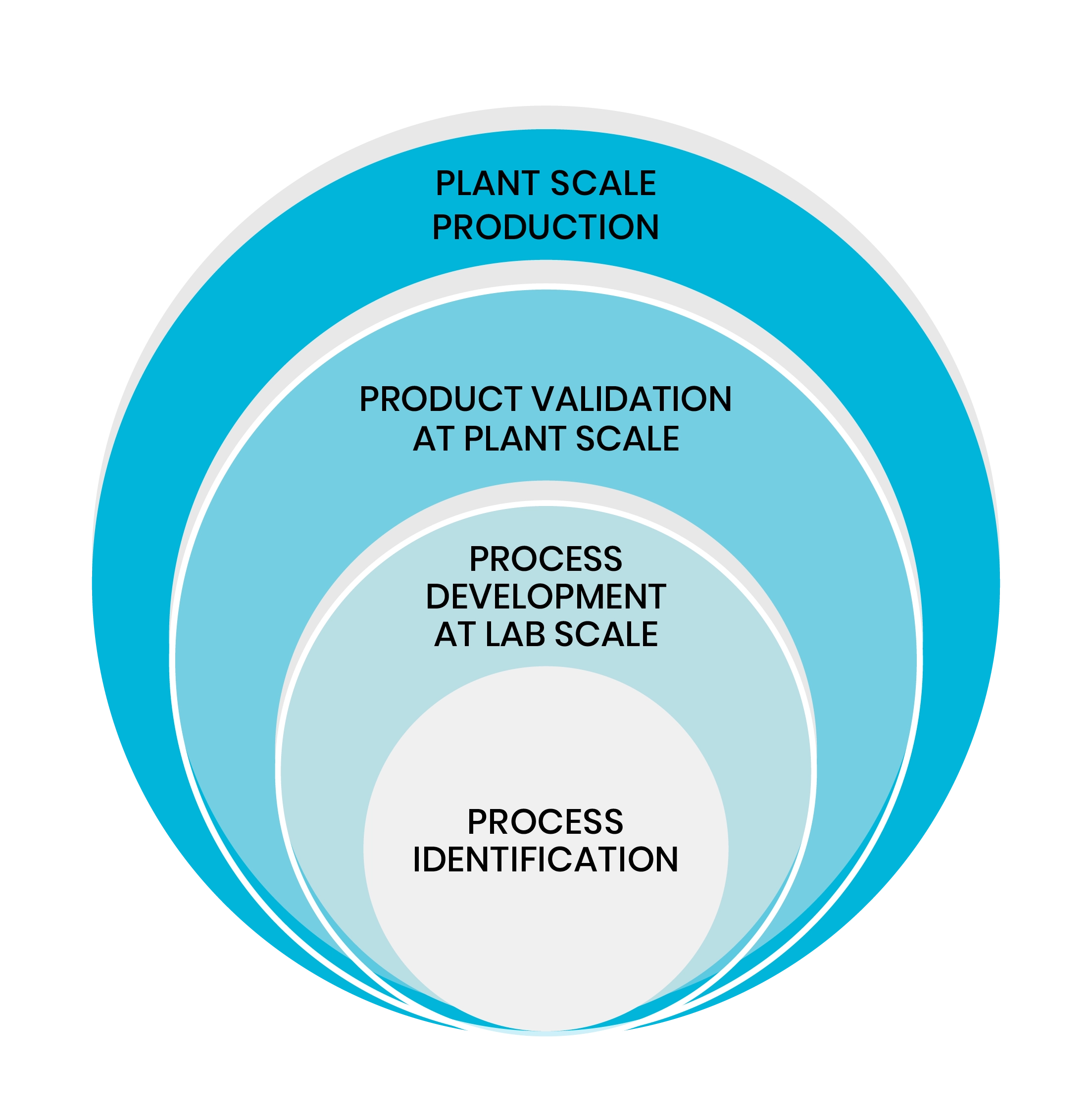

SRDC has an in-house manufacturing plant spread across three floors, designed to handle varied chemical processes with precision and consistency. The facility is equipped with reactors of different sizes, constructed from essential materials of construction such as Stainless Steel (SS), Mild Steel (MS), Glass-Lined Reactors (GLR), Nickel, and Fiber-Reinforced Plastic (FRP). This wide range of materials allows us to manufacture products as per specific process requirements, considering all aspects of production.

Each reactor is supported by the required ancillaries and utilities that enable a smooth and efficient manufacturing process. An integrated data acquisition module is implemented to monitor and log every stage of the reaction and manufacturing process in real time, ensuring control, consistency, and transparency throughout the production cycle.

The plant is equipped with all essential utilities to ensure optimal and uninterrupted operations. In synergy with our Research & Development Lab, the manufacturing facility at SRDC supports both in-house production and Contract Research and Manufacturing Services (CRAMS). This model enables SRDC to offer dedicated project execution in Specialty and Performance Chemistry through well-defined agreements that ensure confidentiality, clear ownership, and customized deliverables providing quality-focused solutions tailored to our customers’ specific needs.